Why More Fleet Managers Are Switching to OKUSLIDE® Liners

At a Glance:

- OKUSLIDE® is corrosion and abrasion resistant, which helps it last longer than steel or aluminium alternatives in harsh conditions.

- The low-friction surface of OKUSLIDE® offers lower tipping angles, which means quicker unloads and fewer rollover risks, even with sticky loads.

- The lighter weight of the OKUSLIDE® liner means more transport materials and better fuel efficiency on every trip.

Fleet managers are expected to keep the fleet in top condition and running at all times. This growing expectation from fleet managers to improve safety, boost efficiency, and reduce operational costs during transportation is resulting in mounting pressure.

That’s why fleet managers in heavy-duty industries, such as mining, construction, and agriculture, are seeking equipment that offers durability, efficiency and long-term value.

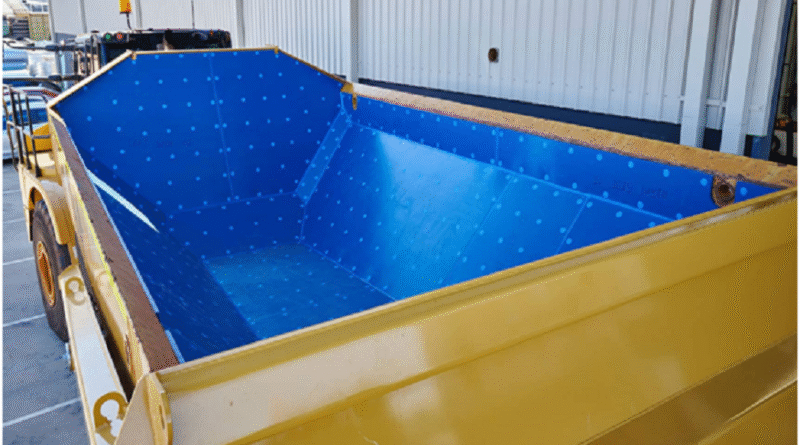

As a result, more and more fleet managers are making the switch to OKUSLIDE® liners. Engineered from ultra-high molecular weight polyethylene (UHMWPE), OKUSLIDE® is fast becoming the preferred alternative to traditional steel and aluminium liners.

In this blog, we will understand why more fleet managers are switching to OKUSLIDE® Liners.

Traditional Liners Don’t Meet Industry Demand Anymore

Steel and aluminium bed liners have long been the go-to bed liners in haulage, probably due to the lack of alternatives.

However, their limitations are becoming increasingly difficult to ignore. For instance, these liners deteriorate over time when exposed to heavy, abrasive, wet, and corrosive materials, which are common in industries such as mining, construction, excavation, and agriculture. Even when protective coatings are applied, metal trays are vulnerable to rust, wear and impact damage.

In such a condition, OKUSLIDE® liners offer the best alternative. The premium bed liners of OKUSLIDE® are made from UHMWPE plastics that are known for their low friction and high abrasion resistance. What does it bring to the table? It brings faster unload times, reduced tipping angles, and no material buildup, among other benefits.

Faster Unloads With Less Tipping

One of the deciding factors for more and more fleet managers to choose OKUSLIDE® liners over other options available on the market is their efficiency in discharging materials at a lower tipping angle. The generic liners require an extreme tipping angle to unload wet and sticky materials, such as clay, dirt, sand, or even mineral ores. In contrast, the liners offered by the OKUSLIDE® reduce the tipping angle by up to 30°.

What does the reduced tipping angle do? First, it reduces hazards and accidental risks, making both operators and vehicles safer. Second, it causes less stress on the vehicle’s hydraulic systems, saving you on maintenance and repair costs.

Lightweight Build Means Bigger Payloads

Steel and aluminium liners are strong, and there is no doubt about that. However, these liners also add unnecessary weight to transport vehicles. At first glance, some extra weight does not seem like a big deal. However, that extra weight limits allowable payload and reduces fuel efficiency across the fleet.

As fleet managers understand this, they opt for a better option like OKUSLIDE®. For instance,OKUSLIDE® Premium Blue reduces the dead weight, thus increasing the usable payload capacity. This can help businesses make more money on the same trip, as they can legally carry more load.

Furthermore, this reduction in weight means that the vehicle’s structure is under less pressure, which in turn increases its lifespan.

No More Material Hang-Ups

Fleet managers who work on-site know how frustrating it is when the load gets stuck and won’t dislodge. This issue causes delays, but that is only one of the many problems. At times, the unloading requires additional labourers or the driver themselves to climb into the tray and manually unload the materials. First, this is not safe, and second, it can disrupt operational efficiency.

OKUSLIDE® eliminates this issue almost entirely. Its non-stick surface ensures even the stickiest loads slide smoothly during tipping. This is a huge win for sectors that transport grain, mulch, wet soil, or demolition waste. With less time spent cleaning out trays, fleet managers can keep vehicles on the move and increase daily load cycles.

Equipment Lasts Longer

Last but not least, fleet managers are choosing OKUSLIDE® as their ideal option because these liners protect the vehicles’ beds from all kinds of wear and tear. Every tonne of material dumped into a truck bed has the potential to cause damage, and over time, those impacts can lead to costly repairs or even early equipment retirement.

That said, OKUSLIDE® provides a durable, impact-absorbing buffer between the load and the vehicle’s surface. It shields the tray from repeated wear and tear, reducing the risk of structural damage and preserving the integrity of the truck body.

Switching to OKUSLIDE® is a strategic move toward a more efficient and reliable fleet operation. The benefits that OKUSLIDE® brings to the table make it easy to see why so many fleet managers in heavy-duty industries are making the change. If you’re in a business that deals with the transportation of heavy materials but is still using the same old bed liners, it might be time to make a switch.

Contact OKUSLIDE® today and optimise your fleet as never before.