How Engineering Plastics Compare to Metals in Industrial Applications

At a Glance:

- Engineering plastics offer high strength-to-weight ratios, making structures lighter without sacrificing performance.

- Plastics naturally resist corrosion, chemicals, and moisture, eliminating the need for protective coatings.

- Lightweight plastics improve energy efficiency in transportation, reducing both fuel consumption and emissions.

- Complex, high-precision designs are easier and more cost-effective to achieve with plastics.

- Advanced plastics maintain stability under moderate to high temperatures, expanding their use in demanding industries.

- Recyclable plastic grades support sustainability goals, even as recycling technologies continue to advance.

Material selection in today’s dynamic industrial age has gone beyond convention. Metals are no longer the only choice; engineering plastics are closing in on them.

As industries push for better performance, cost savings, and sustainable solutions, the choice between engineering plastics and metals becomes more critical than ever. Each material brings its unique strengths and trade-offs to the table, and understanding these differences is key to making informed, application-specific decisions.

In this article, we’ll break down the differences between engineering plastics and metals in various industrial applications with examples.

Head-to-Head Comparison: Engineering Plastics vs Metals

Ease of Manufacture and Processing

Engineering plastics are machineable, can be worked, and moulded with less energy input, allowing more complex shapes to be produced with fewer steps. Products like connectors, switches, printed circuit boards, phone covers, and battery casings rely considerably on advanced plastic materials. Their ability to be successfully moulded into intricate geometries, their lightweight nature, and thermal management properties position them at the centre of making the trend towards device miniaturisation and making higher performance possible.

But, metals demand processes involving more energy, like welding, forging, or casting and are generally best suited for simpler shapes.

Strength and Durability

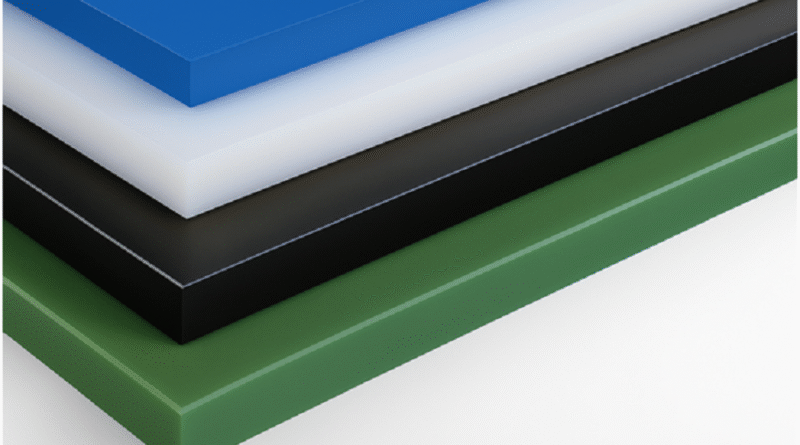

Engineering plastics possess excellent strength-to-weight ratios and are well-suited for most structural requirements. While not as strong as metal in high-stress-load conditions, high-performance plastics like UHMWPE Sheet offer excellent impact resistance, fatigue endurance, and flexibility. They absorb shocks better and are less prone to cracking under dynamic loads.

In medical devices, materials like PEEK and polycarbonate plastics are used in surgical tools and implants because they withstand sterilisation and mechanical stress without degrading. From surgical instruments and disposable syringes to prosthetic limbs and implantable devices, plastics give an assurance of durability, economy, and safety.

In case of metals, they possess the capability of realising better absolute strength and lower fatigue characteristics. Therefore, metals are better suited for high-stress loads and high-load conditions.

Weight and Density

Engineering plastics are lighter in weight and hence improve efficiency in energy use and ease of handling in use and production. This advantage is particularly evident in the aerospace industry. Engineering plastics are now used in cabin interiors, insulation panelling, cargo liners, and even engine parts in the aviation sector. With lighter plastic parts replacing metal parts, aircraft undergo huge weight savings, which restrict fuel consumption, operating expenses, and emissions. High-loading and high-temperature polymers, such as polyimides and PEEKplastic, can resist temperature and mechanical stresses and are increasingly playing a role in modern aircraft design and production.

However, metals are heavy, requiring increased energy for handling and construction.

Corrosion Resistance

Engineering plastics have a natural resistance to corrosion, chemicals, and water without the need for coatings. This makes them ideal for use in water treatment plants, chemical handling, and even under-hood automotive components exposed to harsh fluids and heat.

On the other hand, metals corrode unless covered with a protective coat, painted, or made with specialised alloys. For example, stainless steel is often used in marine or medical applications due to its corrosion resistance, but it requires more care and expense to maintain.

Thermal Stability

Engineering plastics perform well under mid-level temperatures, and high-performance ones are able to sustain higher heat. In aerospace and electronics, materials like PTFE plastic and PEEK serve as insulators and protect components from thermal overload.

On the contrary, metals are the masters of thermal stability, as they can support extreme temperatures, most significantly in aerospace and industrial usage.

Cost Efficiency

Engineering plastics have increased material and processing costs, especially for complex geometries and large quantities of identical parts. However, in industries like logistics automation, plastics used for conveyor system components reduce wear and maintenance, resulting in a lower total cost of ownership.

Metals, on the other hand, have an increased upfront cost, but their strength might be cost-justifiable in the long run, especially with prolonged application.

Design Freedom

Engineering plastics also allow for higher design freedom, which can lead to better fits, generate more attractive designs, and enable the proper substitution of assemblies. This is particularly beneficial in automotive manufacturing, where dashboards, bumper systems, and air intake manifolds are increasingly made of plastics to allow flexible design and styling.

Metals are unable to accomplish this quite so readily as design freedom, other than by utilising difficult and costly processing techniques.

Sustainability

Engineering plastics minimise carbon emissions because they are light in weight, and recyclable options are available, even if recycling streams may be high-tech. In industries like consumer electronics, miniaturised plastic parts support energy-efficient, portable devices.

Metals, even though they are recyclable without loss of properties to infinity, have resource-based production and mining that are environmentally degrading.

Lastly, metal or engineering plastics are not an easy choice. Each material performs best under specific conditions, and understanding when to use one over the other releases new levels of innovation, efficiency, and sustainability.

Having said that, engineering plastics often outperform them in areas that demand corrosion resistance, design flexibility, and weight savings.

So, if you want to discover more about engineering plastics and how your innovations can take flight, contact engineering plastic supplier experts today!